Process engineering services

- Design, construction and installation of oil & gas process equipment etc.

- Design, construction and installation of alcohol plants, barite plants, quick lime plants, agricultural processing and refining plants and equipment.

- Design construction and installation of industrial & Agricultural equipment for wood, bakery, polythene, soap and detergent processing.

Design, construction and installation of oil & gas process equipment.

We have strategic partnership with Original Equipment Manufacturers (OEM) – Indicon Projects & Equipment Ltd, New Delhi, India for the Engineering Design, Manufacturing and supply of Oil & Gas LP and HP Vessels, above & below ground storage vessels including the following:

- Oil & Gas Separation I Filtration / Conditioning Skids

- 213 Phase Separators

- Pressure Vessels Including Scrubbers, Filters, Knock Out Drums (Kod), Receivers with Or Without Skids.

- Shell & Tube Type Heat Exchangers

- Horton Spheres, For LNG, Propane Storage

- Prefabricated Tanks For Water And Petroleum Products Storage Dished Ends

- Scrapper Traps And Receivers With Or Without Skid Chemical Injection, Dosing Skids, and Water Bath Heaters.

Skid Mounted Process Packages & Modular Assemblies

Shell & Tube Heat Exchangers, Evaporators, Condensers.

Design, Construction, and Installation of Various Plants and Equipment:

- Alcohol Plants:

- Design: Developing plans for the production of alcohol, including fermentation tanks, distillation columns, and storage facilities. The design focuses on efficiency, safety, and compliance with regulations.

- Construction: Building the physical structures and systems required for alcohol production, such as fermentation units, distillation equipment, and associated infrastructure.

- Installation: Setting up and integrating the equipment and systems on-site, ensuring they function correctly and meet design specifications.

- Barite Plants:

- Design: Creating layouts and specifications for processing barite, a mineral used in drilling fluids and other applications. This includes crushing, grinding, and separation equipment.

- Construction: Erecting the plant infrastructure, including processing units, storage facilities, and transportation systems.

- Installation: Installing and commissioning the equipment necessary for barite processing, ensuring proper functionality and safety.

- Quick Lime Plants:

- Design: Designing the plant for the production of quick lime (calcium oxide), including kilns, crushers, and conveying systems.

- Construction: Building the necessary structures and systems for lime production, such as rotary kilns and cooling systems.

- Installation: Installing the equipment and ensuring it operates as intended for efficient lime production.

Design, Construction, and Installation of Industrial & Agricultural Equipment:

- Wood Processing Equipment:

- Design: Creating plans for equipment used in wood processing, such as sawmills, planers, and drying kilns.

- Construction: Building the necessary structures and installing the equipment for processing wood into usable products.

- Installation: Setting up and commissioning the wood processing equipment to ensure it functions efficiently and safely.

- Bakery Equipment:

- Design: Designing equipment for baking processes, including ovens, mixers, and conveyors.

- Construction: Building and installing the equipment and associated systems in bakery facilities.

- Installation: Ensuring proper setup and integration of bakery equipment to facilitate efficient and consistent baking processes.

- Polythene Processing Equipment:

- Design: Developing plans for machinery used in the production of polythene products, such as extruders, blow-molding machines, and film rollers.

- Construction: Building the facilities and systems needed for polythene processing.

- Installation: Setting up the equipment and ensuring it operates correctly for the production of polythene products.

- Soap and Detergent Processing Equipment:

- Design: Creating designs for equipment used in the production of soaps and detergents, including mixers, reactors, and packaging lines.

- Construction: Constructing the necessary facilities and systems for processing and packaging soaps and detergents.

- Installation: Installing the equipment and ensuring it is properly integrated and functional for efficient production.

These activities cover the complete lifecycle of industrial and agricultural plant and equipment development, from initial design to final installation and operational readiness.

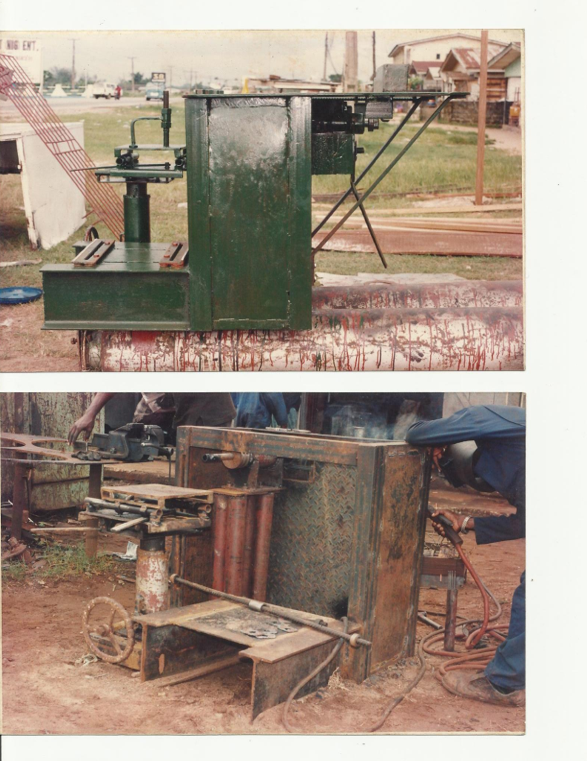

1. CONSTRUCTION OF CORRUGATED PLATE FOLDING MACHINE

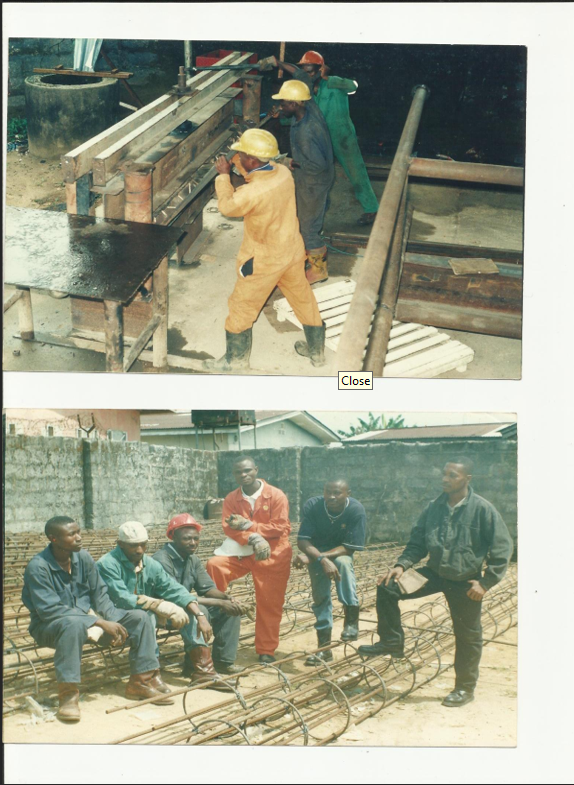

2. CONSTRUCTION OF RE-INFORCEMENT CAGE FOR POWER PLANT/GENERATOR FOUNDATION PILES FOR VICLEY NIGERIA LIMITED – OPUKUSHI F/S OF SPDC – 2002/2003.

DESIGN AND FABRICATION OF WOOD SAWING, MOTICING AND PLAINING MACHINE